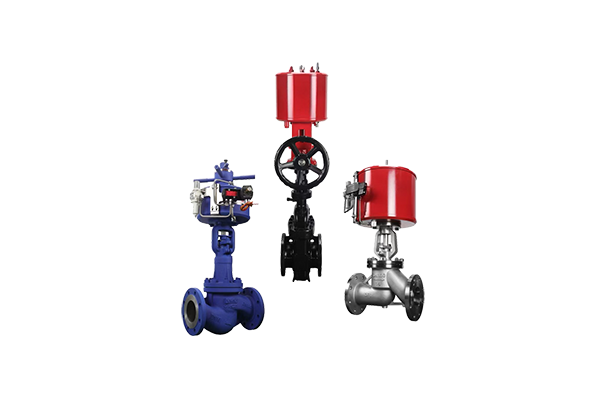

Straight stroke pneumatic actuator G-VH series

The technical team has introduced internationally advanced straight stroke actuator technology and developed a driving device based on the design concept of reliable performance, simple operation, and easy maintenance. The device uses purified compressed

Introduction

1. Design of external reset module 2. Pressure module: cylinder 3. Accessories: bracket

The technical team has introduced internationally advanced straight stroke actuator technology and developed a product with a design concept of reliable performance, simple operation, and convenient maintenance, which is 0.3

A driving device that uses 0.7MPa (gauge pressure) purified compressed air as a power source to drive the piston and achieve valve regulation, opening, and closing functions.

unique advantages

Design standards for G-VH series linear pneumatic actuators: GB/T 12234; Flange standards: National standard GB, Ministry of Machinery standard JB, Ministry of Chemical Industry standard HG; The structural dimensions strictly comply with the IS05211 international standard, and the degree of universality has been increased by one level to meet the needs of convenient and fast installation and after-sales service.

There are multiple different models of straight stroke pneumatic actuators, and accessories such as valve position feedback devices, valve positioners, solenoid valves, air source processors, air/manual switching mechanisms, hydraulic components, etc. can be selected to achieve specialized and powerful functional solutions that can meet various working conditions.

The core components of the G-VH series linear pneumatic actuator have undergone precision machining, grinding, honing, and hard chrome plating, which are not easily corroded, have high hardness, and strong wear resistance. The cylinder sealing ring adopts imported Ding Qing oil resistant ○ - type rubber ring, which has reliable sealing performance and meets the IP65 standard for dust and water protection. If there is an abnormality in the pneumatic actuator, it can be quickly and conveniently switched to manual operation mode to ensure safe and reliable operation.

Product features:

1. Corrosion resistant connectors

All connecting bolts are made of stainless steel and have good corrosion resistance.

2. Piston guide ring

The piston guide ring made of ultra-high molecular weight polymer has an extremely low friction coefficient, and the material has high hardness and excellent wear resistance, providing precise guidance and a long service life.

3. Shell

The interior of the shell is processed with high precision and subjected to anodizing treatment, with an oxide layer thickness greater than 20 μ m, and has a low friction coefficient, excellent corrosion resistance, and wear resistance.

4. Shaft guide sleeve

Prevent direct contact between the shaft and cylinder body, ensure the positioning accuracy of the drive shaft, reduce friction losses, prevent direct contact between the shaft and cylinder body, and ensure smooth operation of the actuator.

5. Piston guide sleeve

Ensure the positioning accuracy of the piston, so that it can run smoothly and smoothly, and prevent movement.

6. Pin connection

The fork and drive shaft are connected by a pin, ensuring synchronous operation of the fork and drive shaft. At the same time, the pin also plays a role in preventing the drive shaft from flying out, which is a reliable and safe design.